How Can Global Capability Centers (GCC) Drive PLM Success?

- Home

- Blog Details

- August 13 2025

- Pankaj Singh

In a hyper-competitive global market, companies are expected to deliver highly personalized, sustainable, and compliant products at an unprecedented pace. The situation creates a critical need for a unified, tactical approach to manage the entire product journey, from initial concept to its final end-of-life disposal.

At its core, Product Lifecycle Management (PLM) is far more than a tool – it is a business strategy integrating people, data, processes, and systems to establish a robust product information backbone. To fully leverage the ability of a PLM system, organizations need to support it with an authoritative and intelligent operational framework. Subsequently, the focus is shifting from mere offshore support to partnering with modern GCCs to transform the PLM function.

Table of Contents

ToggleHow do GCC providers add value to a PLM system?

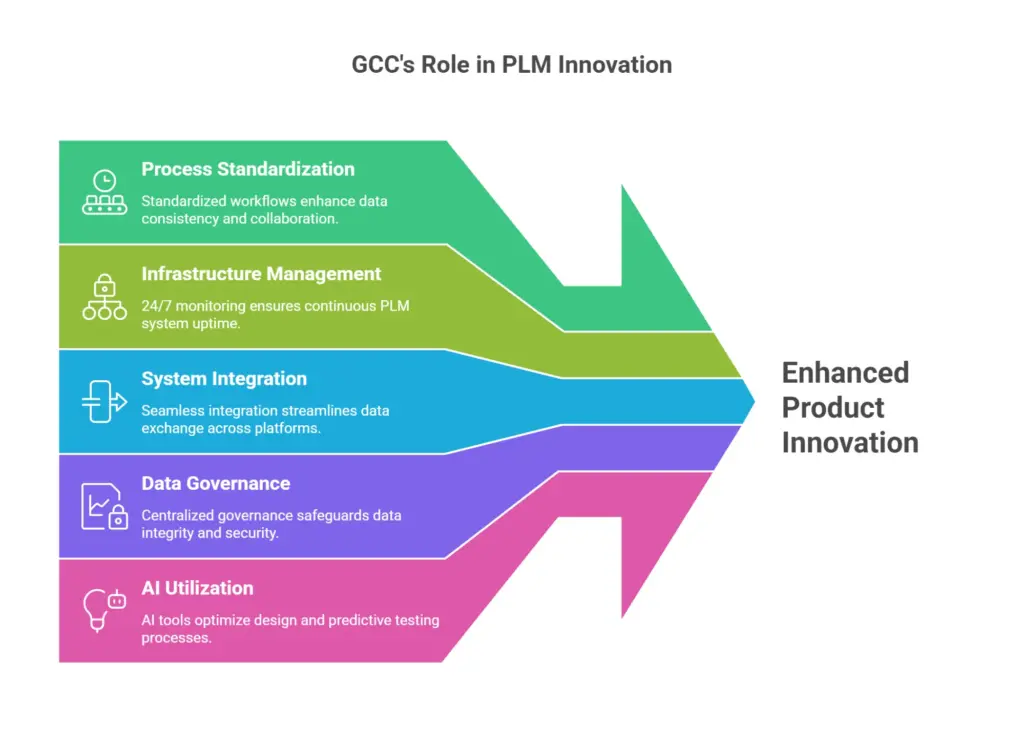

Global capability centers are now widely recognized as transformation catalysts and innovation hubs. These units help drive high-value functions, including research and development (R&D), adoption of artificial intelligence (AI), digital transformation, and advanced data analytics. The way an organization can perceive and utilize GCC will directly influence its capacity for product innovation.

It derives from the fact that PLM demands agility, cross-functional collaboration, and faster, data-driven decision-making, as opposed to a simplistic, task-based support structure. Some of the benefits of teaming up with a GCC provider are –

- Enterprise-Wide Process Standardization

The center develops, documents, and implements standardized PLM workflows and best practices as needed. It can eliminate regional process discrepancies to enhance data consistency and align engineering, manufacturing, and procurement teams under a unified system. The strategy promotes efficiency, improves quality control, and strengthens collaboration among business units.

- Robust 24/7 Infrastructure Management for PLM Systems

Your GCC partner will guarantee continuous, round-the-clock PLM monitoring, maintenance, and performance optimization. A dedicated team is more efficient in providing consistent user support and proactive surveillance to maximize uptime, particularly needed for MNCs operating across multiple time zones. To prevent system disruptions that could impact critical product development timelines, GCCs ensure the centralized data source in PLM always remains accessible.

- Seamless Integration of Complex Enterprise Systems

The core expertise of a GCC makes it economical to undertake tasks such as creating an unbroken digital thread throughout the value chain. It becomes cost-effective to manage integration between the PLM and other core enterprise platforms, including ERP and MES. A seamless data exchange – such as synchronization of engineering bills of materials with manufacturing, inventory, and financial data via PLM-to-ERP connections – is indispensable for PLM success.

- Centralized Data Governance and Uncompromising Security

Under a strong partnership, GCC acts as the central authority on PLM-related data governance, by implementing required security protocols and strictly managing user access controls. The center also delivers organization-wide consistency in data management policies, to safeguard the integrity of product information and core business assets. Experts are responsible for developing and enforcing comprehensive disaster recovery and system redundancy strategies, to protect IP across the PLM environment.

- Harnessing Advanced Technologies like Generative AI

A forward-thinking GCC provider will leverage advanced AI platforms to bolster the PLM process. For instance, it could utilize AI-powered tools to generate and evaluate a vast amount of CAD designs based on specific inputs or criteria, purposed to identify optimal solutions.

According to a 2025 survey by Aras, companies using PLM solutions reported a 28% higher deployment of AI in product development in comparison with non-PLM users. AI is also suitable for predictive testing and simulate performance, to allow early detection of flaws and cut down on late-stage improvement costs.

A GCC-powered PLM transformation is a significant undertaking warranting meticulous planning, executive sponsorship, and a clear understanding of the operational as well as organizational changes involved. A successful implementation depends on three key factors – strategic resource planning, the right operating model, and affirming proper risk management and governance from the start.

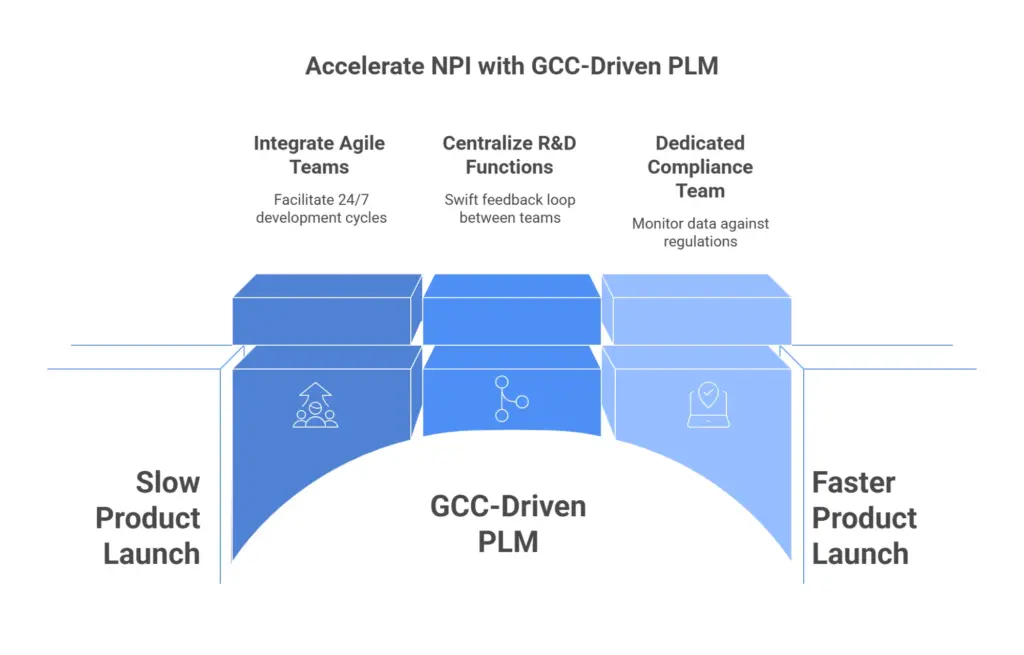

GCC as an NPI Accelerator

The ability to move a product from concept to launch quicker is often the deciding factor in market leadership. A GCC-driven PLM might just be a powerful accelerator for new product introduction (NPI). Integrating agile R&D teams within the GCC facilitates 24/7 development cycles. Projects are seamlessly handled despite different time zones, effectively eliminating downtime and compressing development timelines.

Centralizing R&D and NPI functions within the PLM environment managed by the GCC promises a swift feedback loop between design, simulation, sourcing, and manufacturing. Furthermore, a product’s compliance is determined by its design, material and manufacturing process, which are data sets contained within a PLM system. A dedicated GCC team for compliance can actively monitor and handle the data against international standards and environmental regulations.

Enabling Data-Driven Strategy

A well-built PLM system gathers invaluable business data, like material costs, supplier performance, product quality information, and service histories. But without the right capabilities, this data could remain unutilized in the system, or be merely for historical reporting. A GCC partner with advanced data analytics can transform the PLM from a simple system of record into a powerful tool to harness strategic insights.

An analytics team within the GCC can mine centralized data to communicate actionable intelligence to the client. For example, they can analyze historical data to forecast potential supply chain disruptions, model the cost and timeline impact of proposed design changes, or identify correlations between specific components and in-field failures. The senior leadership is able to embrace a proactive strategy informed by robust data analysis, leading to better, faster, and more beneficial product decisions.

By consolidating technical support, process governance, and data management for a PLM engine, a GCC partner allows an organization to build a stable and secure foundation for global operations. Through the convergence of R&D, advanced analytics, and AI-driven automation within a framework, they are a powerful catalyst for growth. A centralized framework not only provides consistent standards and seamless system performance, but also strengthens compliance, reduces operational risks, and augments data integrity.

Pankaj Singh has extensive experience in market research and content creation within the industrial sector. He currently writes insightful articles related to business, manufacturing, technology, and automation for Prescient Technologies.

- Pankaj Singhhttps://www.pre-scient.com/author/srvprescient/

- Pankaj Singhhttps://www.pre-scient.com/author/srvprescient/

- Pankaj Singhhttps://www.pre-scient.com/author/srvprescient/

- Pankaj Singhhttps://www.pre-scient.com/author/srvprescient/