Vision Inspection System

Our Intelligent Sensing Systems

Sensors We Work With

CCTV

GPS

UWB

BLE

Laser Scanner

Industrial Security

Vision-based Inspection

Defect Detection

Dimension Inspection

Part Segregation

End of Line Inspection

Unleash The Power Of Intelligent Sensing With iNetra

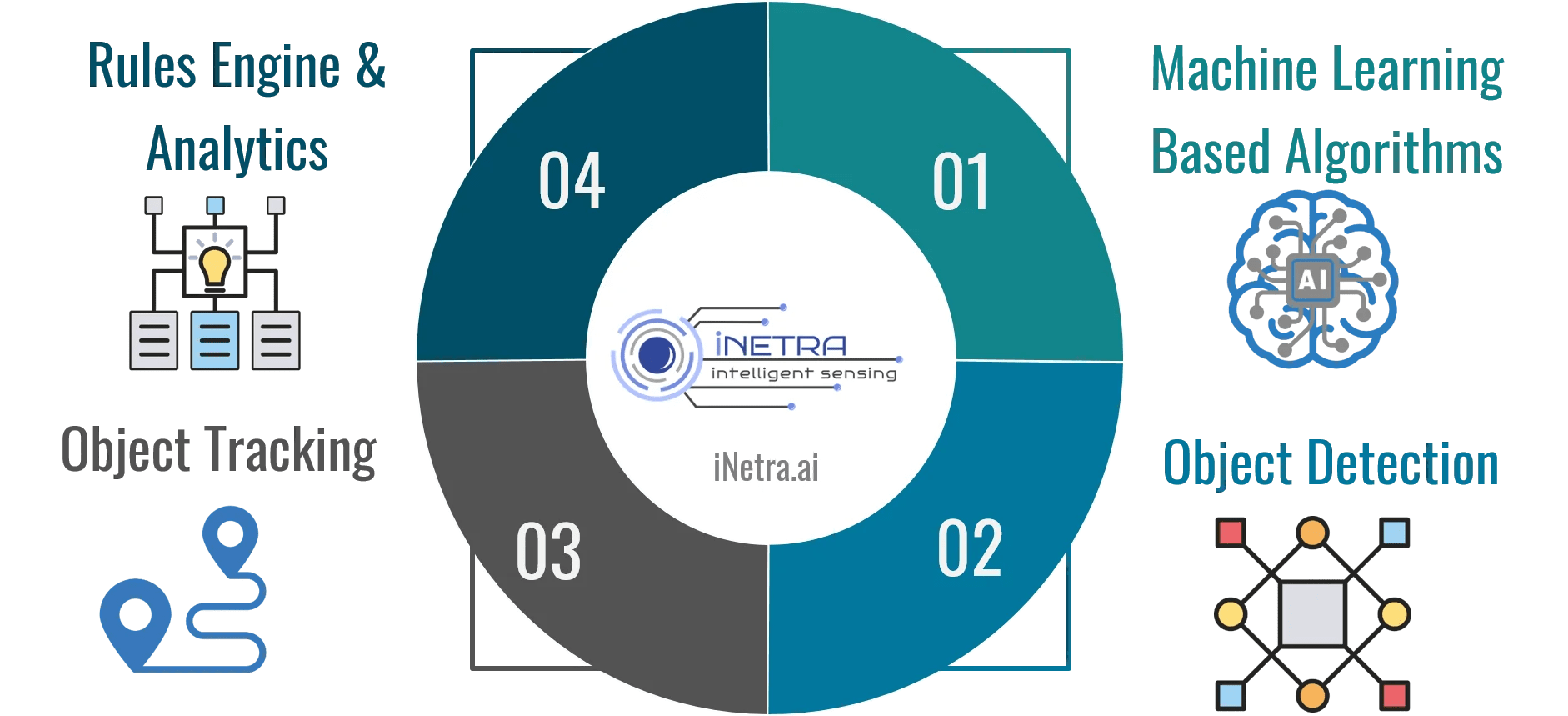

Our Technology Components

Rules Engine and Analytics

Empower your operations with a robust rules engine and analytics suite, enabling real-time insights and decision-making for enhanced productivity and streamlined processes.

Object Tracking

Machine Learning-Based Algorithms

Object Detection

Machine Learning-Based Algorithms

Harness the capabilities of state-of-the-art machine learning algorithms that evolve and adapt to optimize performance, ensuring unparalleled accuracy and efficiency in data analysis.

Rules Engine and Analytics

Empower your operations with a robust rules engine and analytics suite, enabling real-time insights and decision-making for enhanced productivity and streamlined processes.

Object Tracking

Experience precision in monitoring and management with our advanced object tracking technology, offering detailed insights into the movement and behavior of objects within your industrial environment.

Object Detection

Detect anomalies and potential risks with our powerful object detection capabilities, providing proactive identification of issues to prevent downtime and ensure a secure operational environment.

Why Choose iNetra?

Unmatched Quality

Elevate your operations with the gold standard in sensing technology. iNetra is committed to delivering unparalleled quality in industrial inspection and security solutions, setting the benchmark for excellence in the industry.

Transparency in Operations

Trust is the foundation of our partnership. iNetra prioritizes transparency, providing clear and open communication about our processes, methodologies, and results. Experience a level of trust and transparency that empowers your decision-making.

Collaborative Approach

At iNetra, we believe in the power of collaboration. We work hand-in-hand with our clients, fostering a collaborative environment where your insights and feedback are valued. Together, we tailor solutions that align with your unique requirements, ensuring a symbiotic and productive partnership.

Customized Solutions

Tailor our intelligent sensing platform to meet the unique needs of your industry and factory. We understand that every business is different, and our solutions are designed to adapt to your specific requirements.

How does a vision inspection system improve quality control in manufacturing?

It automates the inspection process, detecting defects and errors with high precision, ensuring that only high-quality products move forward in the production line, thus reducing human error and enhancing consistency.

What types of defects and issues can a vision inspection system detect?

It can identify defects like misalignment, contamination, missing components, incorrect labeling, and dimensional inaccuracies, providing comprehensive quality checks.

What industries benefit the most from using vision inspection systems, and why?

Industries such as automotive, electronics, pharmaceuticals, and food production benefit the most due to the need for precision, compliance, and high-volume quality assurance.