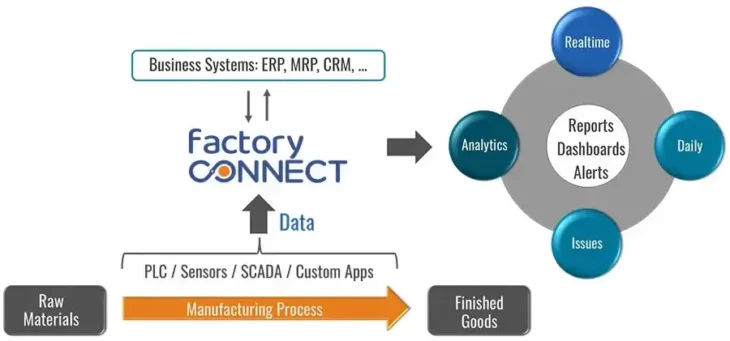

OEE Assessment

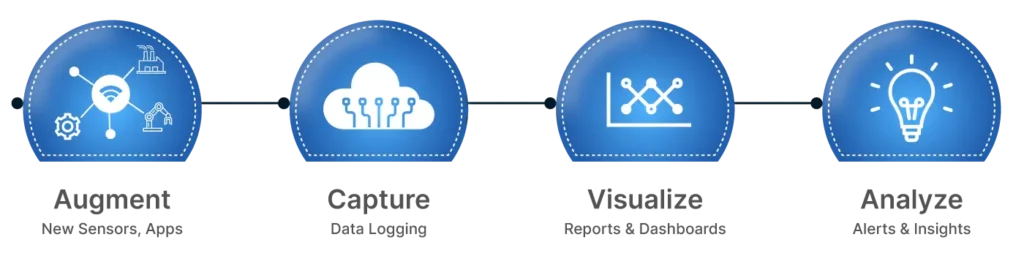

Our experts conduct a comprehensive assessment of your equipment's performance, analyzing key metrics and benchmarking against industry standards. We gain insights into your current performance and identify areas for improvement, tailoring solutions to your unique needs.