The Increasing Prominence of Modularization in Mass Customization

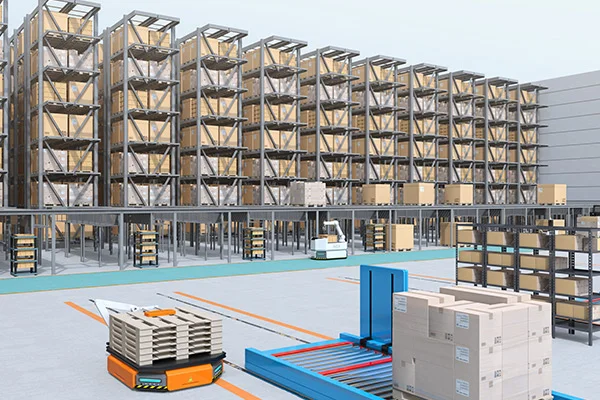

Engineer-to-Order Modularization Industry 4.0 has driven the era of mass customization to inflated levels never seen before in manufacturing history. Accompanied by new-age technologies such as IoT, big data, 3D printing, and robotics, mass customization is executed on an unprecedented scale. Traditionally, the personalization of products was only available at a premium price. Ever since mass customization reached prominence, customers can order customized vehicles, cell phones, clothes and apparels, and even specific task- oriented machinery delivered on time. It has been possible due to the dramatic automation and modularity of workspaces that can be rapidly configured and then reconfigured to adapt to different specifications supplied by the customer. Mass customization trend is evident in both B2B and B2C sectors. Industries such as aviation, construction, glass, and ceramic manufacturing have adopted mass customization with a particular emphasis on 3D printing to a great extent. An exciting aspect of mass customization is lean customization, a just-in-time (JIT) inventory system, and digital tech to produce items with lesser costs. Lean customization allows consumers to select their preferred designs and colors at no extra cost to the company. Since lean customization involves a specific batchwise production process, it can be implemented in the well-known crafting specialty strategy known as Engineer-to-order. Engineer-to-Order Engineer-to-order means craftsmanship where production is tailored for specific customer requirements. It means the entire research and development, design, and build is suited for certain specifications, and it differs from customer to customer. Although such productions offer a great deal of personalized content to the customers, it comes with reasonable operational costs, making the product quite expensive. So, the prime goal is to reduce operating costs which will reflect on the product’s price. Incorporating lean customization into engineer-to-order addresses this issue, getting modular work processes. Modularization About 100 years ago, Henry Ford presented the first assembly line to the automotive industry. Since then, auto manufacturing has primarily been in a fixed and sequenced line, operated by pre-defined and rigid processes. Once an assembly line is defined for a specific model, it cannot be modified throughout the entire product’s lifecycle and commands over the intra-logistical methods of the production and supply chain. The auto manufacturers had to incur huge costs if they wanted to release a modified model since it involved creating an entirely different assembly line. This issue is not limited to car manufacturing but also apparel, chemical, and pharma industries. To address an agile and flexible production process, the industry is using the concept of modularization. Modularity essentially refers to the capability of a system to be reconfigured on a plug-n-play basis, thereby allowing it to respond to changes in customer requirements quickly and efficiently. Audi is one such company that has created independent workstations, each assigned a particular production function. Unfinished cars move autonomously from one workstation to the other, with the help of driverless transport systems (DTS), where connected robots and a few humans assemble a particular part of the car. Suppose one DTS reaches a station that is already occupied. In that case, it is programmed to head to another available station, thereby removing the delays part of the conventional assembly line. This modular assembly also allows for changes to be made on the go. The key advantages of modularization include: Modularization involves taking in requirements and specifications from customers and passing them off to the production floor directly without any significant engineering maneuver in between. Thus, it needs a rule-driven production that regulates how modularization is successfully achieved. To enforce a well- functioning and effective rules-driven production system, manufacturers can take these three steps: Modularization is the key to unlocking mass customization. By breaking down a product into smaller, more manageable parts, it becomes easier and faster to produce customized versions of that product. It also becomes more cost-effective, as each individual component can be produced in larger quantities. It is good news for consumers who want unique products without paying a premium price and for businesses who want to offer those unique products without breaking the bank.

Read More