Reverse Engineering CAD Engineering Services

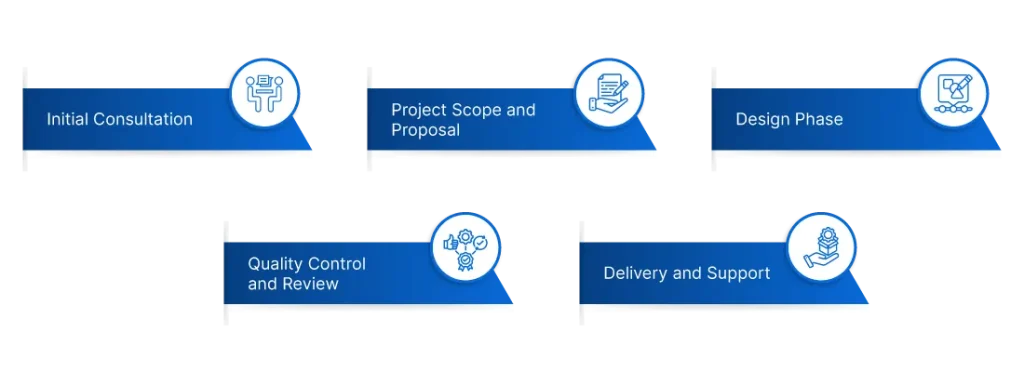

Are you looking for high-quality and accurate 3D CAD design services for your next project? Look no further! Our team of experienced CAD specialists is here to help you bring your designs to life. We offer a wide range of CAD design services, including 3D modeling, 2D drafting, conversion, and migration services. Our CAD design process is transparent, efficient, and collaborative. We work closely with our clients to understand their requirements, and we provide regular updates throughout the design process to ensure that the final designs meet their expectations. Our process includes an initial consultation, project scope and proposal, design phase, quality control and review, and delivery and support. With our CAD design services, we can assure you of working with experienced CAD specialists who deliver quality work on time and at a competitive price.

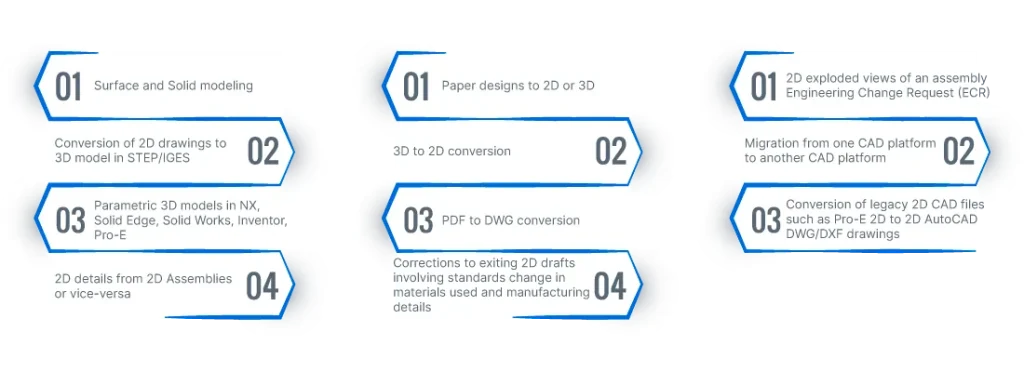

Our CAD specialists have extensive experience in building 3D models, ranging from simple designs to complex assemblies, using a variety of software tools such as NX, Solid Edge, SolidWorks, Creo, Autodesk Inventor, CATIA, and more. We work closely with our clients to understand their requirements and provide accurate 3D models that meet their needs.

We understand the importance of accurate 2D drafting in the CAD design process, and we offer drafting services that cover all your needs. Our drafting services include converting your paper drawings and blueprints to digital formats, creating 2D drawings from 3D models, and drafting services for files from other CAD software platforms. We use industry-standard software tools such as AutoCAD and SolidWorks to create accurate and unambiguous 2D drawings that convey all the required information to the manufacturer.

We understand that many companies have legacy data in various file formats, and we offer conversion and migration services to help you move your data to a more modern platform. Our conversion and migration services can cover all your paper drawings, blueprints, and even files from other CAD software platforms. We can convert files to and from various formats, ensuring that you can work with your data in the software tools of your choice. We also offer additional services such as rendering and simulation, product design and development, reverse engineering, and more. Our team of CAD specialists has extensive experience in a wide range of industries, including aerospace, automotive, consumer products, and medical devices, among others. We pride ourselves on providing quality work, timely delivery, and competitive pricing to ensure customer satisfaction.

Conversion of 2D drawings to 3D model in STEP/IGES

Professionalism and work ethics… "The level of professionalism and work ethic you bring to the table is simply great. The fact that clicked the most is when you took complete responsibility for our product development and the outcome is exactly what we desired. Thank you Prescient."

First on our list, without doubt … “I greatly appreciate the software development work you have been doing for Level 3 Inspection for all these years. Your team’s skills and your methodical approach to perfection, coupled with your high level of professionalism, have made the road pretty smooth for us to achieve our organizational and operational integration goals. If we have to recommend a competent partner we can totally depend on, your name would be the first on our list, without a doubt. Thank you Prescient!”

They are the exception... "We've been working with Prescient Technologies for quite a few years now, and they continue to provide quality work in a timely manner for a reasonable cost. They are the exception to the two out of three rule! (Fast, High Quality or Good Price, pick two)"

There could not have been a better alternative… "It was a chance meeting with the Prescient team that set the ball rolling. Initially I was skeptical but their attitude “Together we can” inspired confidence. ”Hand-holding” by Prescient was exemplary and that was crucial for a start-up like ours. Our project in Orthopaedic navigation involved totally new objectives in as yet unexplored areas to be achieved with innovative steps in CAD domain. Few years down the line together we have added a chapter at the very edge of scientific knowledge. Thanks to Prescient our software idea has now evolved into a full-fledged market-ready product. Today I am convinced that there could not have been a better alternative."

Professionalism and work ethics… "The level of professionalism and work ethic you bring to the table is simply great. The fact that clicked the most is when you took complete responsibility for our product development and the outcome is exactly what we desired. Thank you Prescient."

Our CAD design services are suitable for a wide range of industries, including manufacturing, automotive, aerospace, defense, architecture, and many others. We have experience in creating 3D models and 2D drawings for various products, components, and systems.

Our team of CAD specialists has expertise in using a variety of software tools, including NX, Solid Edge, SolidWorks, Creo, Autodesk Inventor, CATIA, and more. We can work with the software tools of your choice.

Yes, we offer conversion and migration services that can cover all your paper drawings, blueprints, and even files from other CAD software platforms. We can convert your paper drawings or blueprints into 3D models and 2D drawings that are accurate and high quality.

The timeline for a CAD design project depends on the complexity of the project, the scope of work, and the number of revisions required. We will provide you with a timeline estimate during the initial consultation phase.

Yes, we encourage our clients to provide feedback and request changes or revisions to the designs throughout the design process. We will work closely with you to ensure that the final designs meet your requirements and expectations.

We have a rigorous quality control and review process that includes multiple checks and tests to ensure the accuracy and quality of the CAD designs. Our team of CAD specialists also has extensive experience in creating 3D models and 2D drawings that are precise and reliable.

Yes, we offer CAD design services for both prototypes and small production runs. Our team can work with you to design and create 3D models and 2D drawings that are optimized for manufacturing and production.

Yes, we are committed to protecting the confidentiality and intellectual property of our clients. We are happy to sign an NDA or any other legal agreements that are required to ensure the protection of your information and designs.

We can deliver the final CAD designs in a variety of file formats, including IGES, STEP, STL, PDF, and others. We will work with you to determine the best file format for your specific needs and requirements.

The global market is demanding a version of steelmaking that is faster, cleaner, and significantly more efficient. Why? Decades-old infrastructure in some regions, massive capital assets, and a workforce where traditional knowledge is going out as the older generation of labor enters retirement. The industry-wide pressure for modernization is driven by rising energy prices and unstable raw material costs. Add to that aggressive sustainability targets that look more like mandates than goals. In this environment, digital twin technology is moving into the limelight as a survival kit. The process is about creating a living, virtual replica of a physical asset that mirrors real-time operations, allowing engineers to peek into the future. 1. Defining the Global Steel Digital Twin A digital twin in steel manufacturing is a dynamic computerized simulation of a real, physical object, process, or complete production system. Unlike a static CAD model, a digital twin is continuously linked to plant data available through sensors, distributed control systems (DCS), historians, andmanufacturing execution systems (MES). In a steel plant, these twins are applied to all the high-stake assets; 2. Operational Value Drivers for Digital Twin in Steel Plants 2.1 Predictive Maintenance – Extend Asset Lifecycle Continuous operation means failures occur at any time, and traditional maintenance is either reactive or preventive. Both are inefficient. Digital twins are revolutionizing maintenance with AI-powered pattern recognition. By monitoring vibration, temperature, and acoustics, the system can identify the “digital signature” of a failing part before a catastrophic breakdown. For example, a digital twin can identify unusual vibrations in a rolling mill and allow maintenance to be scheduled proactively. This reduces unplanned stops by up to 30% and extends the lifespan of critical equipment. 2.2 Quality Control – Deliver with Precision, at Scale Ensuring product quality is a big concern as customer specifications from automotive and aerospace sectors become more stringent. Small variations in chemical composition or temperature can lead to costly rejections. If the twin detects a temperature drift, it can recommend immediate adjustments. In some advanced setups, these adjustments are handled autonomously by AI agents. This is where technologies like iNetra (an AI vision inspection system) become essential. By integrating intelligent sensing, steelmakers can conduct end-of-line inspections that catch flaws invisible to the human eye, ensuring every ton meets requirements. 2.3 Energy Efficiency – the “Green Steel” Imperative The global steel industry is under immense pressure to decarbonize. Sustainability is the defining trend for 2026 and beyond. Managing energy consumption is crucial for cost control and ESG compliance. With digital twins, manufacturers can simulate different scenarios to find the most energy-efficient path. For instance, a twin of an electric arc furnace (EAF) can suggest changes in energy input based on the specific material composition of the scrap being melted. When combined with an Energy Management Information System (EMIS) like powerCONNECT, these twins provide the granular data needed for real-time energy monitoring. It helps enterprises reduce power consumption and align with net-zero target roadmaps, without sacrificing production speed. 3. Integrating with Legacy Systems and Data Silos Most steel manufacturing facilities rely on legacy systems. They have layered, incompatible systems added and linked over decades. Here, the primary hurdle isn’t the AI; it’s the data. Data is often trapped in siloed systems across legacy setups. For instance, maintenance logs are stored in one database, sensor data in another, and production metrics in a third. For a digital twin to work, clean data is required, but many plants still depend on manual paperwork rather than a centralized system. Successful digital twin implementations involve a modular approach, as a complete system overhaul can introduce massive operational risks. There are also hardware issues to sort. Standard sensors cannot be near a blast furnace. High-temperature environments impact sensor durability and lead to signal noise. Manufacturers are looking for advanced sensing solutions that include damage-resistant insulation and humidity control. It ensures the data reaching the twin is accurate. 4. Digital Autonomy for a Resilient Future Global digital twin market size is anticipated to exceed US$240 billion by 2032, with manufacturing sector adopting the technology faster than other industries. It is not just a trend anymore. It is a fundamental shift in how steelmakers can grow in a volatile, high-stakes industry. Because steel manufacturing is energy-intensive, physics-heavy, and involves extreme environments, it is an ideal process for digital twin implementation. For steelmakers considering digital twins, a key takeaway is the resilience. With volatile raw material prices and a shrinking workforce, the technology provides a layer of stability. Enterprises can ensure that the expertise of existing operators is codified into the system and that the furnace keeps running at peak efficiency even when the external environment is challenging.

Read More1. Scaling Beyond the Pilot According to International Data Corporation, enterprises across the manufacturing, energy, and heavy equipment sectors were projected to spend nearly US$4 trillion on digital transformation by 2027. However, the success rate for most of these initiatives isn’t ideal. This is a global problem. For a sector accustomed to mechanical precision and tangible assets, the complexities of software-defined operations can be challenging. When these investments fail, the costs also include a loss of strategic momentum and damaged brand reputation. Digital transformation is not a singular event; it is a continuous process of integrating advanced technologies, ranging from Product Lifecycle Management (PLM) systems such as Teamcenter, to AI and the Internet of Things (IoT). 2. The Digital Transformation Risk Landscape 2.1 The Human Factor: McKinsey and other researchers consistently find that organizational culture is a significant obstacle to digital transformation. Organizations that prioritize cultural change alongside technology see higher success rates than those only focusing on the tools.Also, over 90% of manufacturers face workforce shortages worldwide. As seasoned technicians retire with decades of institutional knowledge, younger workers often lack the hands on experience required to manage complex machinery.To de-risk this, global firms are using technology as a capability multiplier through upskilling, rather than a replacement for human expertise.Manual design workflows rely heavily on human memory and discipline. Engineers follow guidelines. They apply standards. They check compliance. This works at small scale. 2.2 Technical Debt and the Legacy Systems: In heavy industries, enterprises often operate across several legacy systems. In the manufacturing sector, more than 70% of enterprises struggle to innovate because of constraints imposed by outdated technology. These systems were built before the era of cloud computing and advanced analytics, creating significant integration challenges. The cost of maintaining legacy infrastructure is the technical debt that complicates modernization attempt. True digital transformation creates an integration layer, a decision system that links technologies into a unified operational model. It is about building a system where information flows automatically across manufacturing workflows, enabling people to act on real-time data. 2.3 Establishing the Digital Thread via PLM: For many global manufacturers, a robust PLM implementation serves as the backbone of the digital thread, which is the flow of data from initial design through engineering and into service. However, the risk during a PLM data migration is often underestimated. Enterprises with thousands of SKUs and decades of historical data face significant challenges in mapping old system structures to modern schemas. A common failure point is over-customization. Tailoring the software to every existing manual process increases the maintenance burden and makes future upgrades riskier. De-risking here involves a Minimum Viable Product approach, locking the scope to essential features first and using phased releases to add complexity later. 3. Strategic Framework for De-risking Implementation 3.1 Data-Backed KPI Selection Do not aim for broad, vague goals from the beginning. 3.2 Building Cross-Functional Teams Technical talent alone is insufficient. 3.3 Rapid Prototyping Build leadership confidence via early wins. 3.4 Embedded Learning Upskilling must happen in parallel with the technology rollout. 3.5 The “Continue/Pivot/Stop” Protocol Transparency is essential. 4. The Decision System: The Final Frontier Digital transformation is about the decision system. A transformed factory fundamentally rethinks its processes. For instance, if an enterprises gains real-time data from a digital twin, its weekly production meeting shouldn’t stay weekly just because that’s the tradition, it should happen when the data dictates it. Derisking digital transformation is not a task that can be delegated entirely to the IT department. It requires a strong commitment from leadership to unify business strategy and technology execution. The blueprint for success in 2026 and beyond is clear; prioritize the human factor, address legacy debt through strategic PLM implementation, insist on technical interoperability, and follow a phased, data-backed roadmap.

Read MoreEngineering teams face a familiar problem. Designs look correct at first. Issues appear later. Errors surface during manufacturing or testing. Rework follows. Costs rise. Timelines stretch. This cycle affects productivity and trust. You may already feel this pressure in your projects. Complex CAD models. Manual updates. Repeated checks. Small mistakes that turn into major delays. This is where Design automation in engineering starts to matter. This blog explains why engineering errors happen so often. It also shows how automation helps you reduce them in a practical way. Engineering Errors are Still Too Common Engineering errors do not always come from lack of skill. They often come from repetitive tasks and manual processes. Design engineers handle – Each step introduces risk. A missed dimension. A wrong constraint. An outdated design rule. These errors move quietly through the workflow. According to recent manufacturing software coverage from TechCrunch, engineering teams spend a large share of project time fixing issues that could have been avoided earlier in the design phase. The article highlights that rework continues to drain engineering capacity across industries, especially in high-mix manufacturing. When errors pass into production, the impact grows. Scrap increases. Machines sit idle. Teams rush to correct designs. Customer confidence may drop. You may ask yourself: How can I reduce engineering errors through automation?The answer starts with understanding how design work is done today. Why Manual Design Work Leads to Rework Manual design workflows rely heavily on human memory and discipline. Engineers follow guidelines. They apply standards. They check compliance. This works at small scale. Problems appear when – Manual checks do not scale well. Even experienced engineers can miss steps during tight deadlines. Wired recently discussed how modern engineering environments overload designers with data, rules, and variants. The article noted that cognitive load increases error rates when processes remain manual and fragmented. Rework creates a chain reaction – Each correction adds cost. Each delay reduces competitiveness. This is why many teams now ask: What is design automation in engineering?They want a system that reduces dependency on manual intervention. Design Automation in Engineering Design automation in engineering refers to using software-driven rules, logic, and templates to create or modify designs automatically. It replaces repetitive tasks with controlled processes. Automation does not remove engineers from the process. It supports them. It ensures consistency. It applies rules every time without fatigue. At its core, design automation – This approach helps you reduce engineering errors with automation at the source. How Design Automation Improves Engineering Accuracy 1. Rule-Based Design Enforcement Automated systems embed engineering rules directly into the design process. Tolerances. Material limits. Compliance rules. All enforced automatically. This answers a key concern: how design automation improves engineering accuracy in real projects. When rules are built into the model: Lucent Innovation’s recent engineering automation blog explained that rule-driven design reduces downstream corrections because issues are identified during model creation, not after release. 2. Consistent Design Output Across Teams Manual workflows depend on individual habits. Automation standardises outcomes. Automated templates ensure: This consistency reduces misinterpretation during manufacturing and inspection. 3. Automated Engineering Workflow Improvement Design automation also supports automated engineering workflow improvement by connecting steps that were previously isolated. Automated workflows can: TechNewsWorld reported that integrated engineering workflows reduce handoffs and version conflicts, which remain a top source of errors in distributed teams. 4. Reduced Dependency on Manual Checks Automation performs checks continuously. It does not wait for reviews. It does not skip steps. This reduces: Engineers focus more on innovation and less on repetitive validation. Best Practices for Reducing Rework in Engineering You may already use CAD tools. Automation works best when applied with intent. Here are best practices for reducing rework in engineering using automation: Engadget recently highlighted that companies see better results when automation is introduced gradually and aligned with existing processes. Design Automation in Real Manufacturing Environments Manufacturing companies across North America, Europe, and India now adopt automation to manage complexity. In high-variant production: Talentica’s engineering automation insights show that companies using design automation report fewer engineering change orders and shorter design cycles. This matters for factory owners and engineers managing tight production schedules. Where Prescient Technologies Fits In Prescient Technologies has deep experience in CAD and engineering software development. The company works closely with engineering and R&D teams to build automation where it matters. Prescient’s approach focuses on: These solutions support design accuracy and reduce manual dependency. Tools like factoryCONNECT, machineCONNECT, and powerCONNECT help extend automation beyond design into production and monitoring. This alignment reduces design-to-manufacturing gaps. Key Takeaways Design automation does not replace engineering judgement. It supports it. Ready to Reduce Errors in Your Engineering Workflow? If you want to explore how automation can fit into your design environment, Prescient Technologies can help. Connect with the Prescient team to learn how factoryCONNECT, machineCONNECT, and powerCONNECT support automated design and manufacturing workflows. These solutions are built to reduce rework and improve accuracy across engineering operations. You can take the next step toward fewer errors and more predictable outcomes by exploring Prescient Technologies’ engineering automation offerings today.

Read More