Evaluating ROI: Measuring the Impact of Additive Manufacturing Implementation

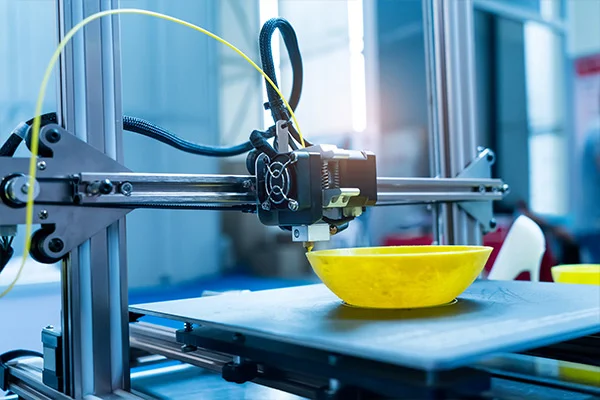

Table of content Introduction Understanding Additive Manufacturing Challenges and Considerations in Additive Manufacturing Implementation Future Trends and the Evolving Landscape of Additive Manufacturing ROI Conclusion Introduction The ability to produce complicated parts with remarkable speed and efficiency thanks to additive manufacturing, often known as 3D printing, has completely changed the industrial sector. Businesses are becoming more concerned with assessing the return on investment (ROI) related to using additive manufacturing solutions as the technology develops and becomes more widely used. This article looks at several aspects of additive manufacturing implementation and how organizations may evaluate their ROI effectively. Understanding Additive Manufacturing Additive manufacturing is a process that builds three-dimensional objects by adding successive layers of material based on a digital model. This technology offers numerous advantages over traditional manufacturing methods, including reduced lead times, lower costs, design flexibility, and the ability to produce complex geometries. These benefits have attracted a wide range of industries, including aerospace, automotive, healthcare, and consumer products, to incorporate additive manufacturing into their operations. Measuring ROI in Additive Manufacturing Assessing the costs, advantages, and dangers of implementing additive manufacturing is necessary to calculate the return on investment. When assessing the effects of additive manufacturing on your company, keep the following points in mind: Cost Analysis Begin by analyzing the costs associated with implementing additive manufacturing. This includes the cost of acquiring 3D printers, software, materials, and training. Additionally, consider the costs of maintaining and operating the equipment, as well as any required facility modifications. You can estimate the financial impact by comparing these costs with the potential savings due to additive manufacturing. Operational Efficiency Additive manufacturing can considerably increase operational efficiency because lead times are shortened and supply chains are made simpler. Analyze the potential for time and money savings in your production processes by using additive manufacturing. One method to save assembly stages and material waste is to combine several pieces into a single 3D-printed component. Design Optimization Another key advantage of additive manufacturing is design flexibility. Traditional manufacturing methods often have limitations on complex geometries, but additive manufacturing allows for intricate designs with minimal constraints. Assess how this design freedom can enhance product performance, reduce material usage, and enable innovation. Consider the potential cost savings and revenue generation resulting from optimized designs. Customization and Personalization Additive manufacturing enables customization and personalization at scale. Evaluate the market demand for customized products and assess how additive manufacturing can help meet these requirements. Customized products often command higher prices, leading to increased revenue potential. Supply Chain Optimization Due to its ability to support decentralized production and on-demand manufacturing, additive manufacturing has the potential to upend conventional supply chains. Consider the effects of localized manufacturing, lower transportation costs, and advantages of inventory management. Take into account the potential reduction in lead times and the capacity to react swiftly to demand fluctuations. Risk Management Like any investment, additive manufacturing comes with inherent risks. Evaluate the potential risks associated with implementing the technology, such as operational challenges, quality control, intellectual property concerns, and regulatory compliance. Mitigate these risks by developing robust strategies and considering them in your ROI calculations. Quantitative and Qualitative Factors Take into account both quantitative and qualitative considerations when assessing the ROI of additive manufacturing. Cost reductions, income growth, increased productivity, and less waste are examples of quantitative metrics. Improved consumer happiness, increased market competition, and the capacity to develop novel products are examples of qualitative metrics. Market Expansion and New Business Opportunities Additive manufacturing opens up new business opportunities and market expansion possibilities. Evaluate how implementing this technology can allow you to enter new markets, cater to niche customer segments, or offer unique products and services. Consider the potential revenue growth from tapping into previously unexplored markets or creating innovative business models based on additive manufacturing capabilities. Challenges and Considerations in Additive Manufacturing Implementation There are certain difficulties and things to think about in additive manufacturing implementation. Despite the fact that the technology has many advantages, businesses should be aware of any obstacles that could reduce the overall return on investment. Consider the following major difficulties: Initial Investment The initial investment required for additive manufacturing implementation can be substantial. Organizations need to assess their financial capabilities and determine if they have the necessary budget to acquire the equipment, software, and training required for successful implementation. Conduct a thorough cost analysis and consider alternative financing options if needed. Material Selection and Quality Control Additive manufacturing relies on various materials, each with its own unique properties. Organizations must carefully evaluate material options to ensure they are suitable for the intended applications. Maintaining consistent quality control throughout the additive manufacturing process is crucial to avoid defects or deviations in the final products. Intellectual Property and Data Security Additive manufacturing involves the use of digital models and designs, which can be susceptible to intellectual property theft or unauthorized replication. Organizations must implement robust security measures to protect their intellectual property and ensure data integrity throughout the additive manufacturing workflow. Future Trends and the Evolving Landscape of Additive Manufacturing ROI As additive manufacturing continues to evolve, several future trends will shape the ROI landscape. Understanding these trends can help organizations assess the long-term impact of additive manufacturing implementation. Here are some noteworthy trends: Conclusion As additive manufacturing continues to reshape the manufacturing landscape, evaluating the ROI of additive manufacturing implementation is crucial for organizations considering adopting this technology. It involves considering the challenges and considerations, examining real-world case studies, and understanding future trends in the additive manufacturing landscape. By carefully assessing the costs, benefits, and risks associated with additive manufacturing implementation, organizations can make informed decisions that maximize the ROI and leverage the full potential of this transformative technology. With ongoing advancements and increasing adoption, additive manufacturing will continue to reshape industries, drive innovation, and deliver substantial returns for forward-thinking organizations. Interested in transforming your manufacturing processes? Discover the impact of additive manufacturing implementation on your business. Evaluate ROI, explore case studies, and stay ahead of the evolving landscape. Embrace the

Read MoreOptimising Additive Manufacturing: Unleashing the Power of Slicing Algorithms

Table of Content Introduction Slicing algorithms: An understanding Types of Slicing Algorithms Optimisation Techniques Conclusion Introduction The industrial sector has transformed because of additive manufacturing, often known as 3D printing, which makes it possible to produce intricate geometries more effectively and affordably. The slicing algorithm is an essential part of the additive manufacturing process. Slicing algorithms help the printer deposit materials layer by layer by decomposing a 3D model into a sequence of 2D levels. The significance, varieties, and effects of additive manufacturing slicing algorithms on the calibre, speed, and accuracy of the manufacturing process will all be explored in this article. We will also review the optimisation methods used to improve slicing algorithm performance for better additive manufacturing results Slicing algorithms: An understanding At its core, additive manufacturing involves the layer-by-layer construction of a physical object based on a digital model. The slicing algorithm serves as the bridge between the digital model and the material creation. It takes the 3D model and slices it into a series of 2D layers, then translates it into machine instructions for the 3D printer. Each layer is a horizontal cross-section of the object that the printer will fabricate. Layer thickness, infill density, support structures, and printing path are just a few of the crucial factors slicing algorithms consider. While the infill density specifies how much material is utilised to fill the interior of the item, the layer thickness controls the print’s vertical resolution. Support structures are created to stabilise overhanging elements during printing, and the printing path defines the order in which the printer deposits material. Types of Slicing Algorithms In additive manufacturing, a variety of slicing algorithms are used. Each method has advantages and disadvantages, and the choice of one depends on the particular specifications of the printed product. Several popular slicing algorithms are listed below: Uniform Slicing Collect knowledge from subject matter experts, books, journals, and other sources, then organise it so a computer can process it. Adaptive Slicing This algorithm dynamically adjusts the layer thickness based on the object’s geometry. When there are smooth slopes, the layer thickness increases; when there are sharp features, the thickness decreases. Adaptive slicing improves The staircase effect, and the surface quality is lessened. Tree-like Slicing The printing path is optimised via tree-like slicing methods. These algorithms construct a hierarchical structure as opposed to strictly adhering to a layer-by-layer method, enabling the printer to optimise its movements and reduce travel times. As a result, printing takes less time and is more effective overall. Non-Manifold Slicing Non-manifold slicing algorithms can effectively handle complex geometries featuring overlapping surfaces and non-manifold edges, which is crucial for ensuring successful 3D printing. These algorithms play a vital role in detecting and rectifying any inconsistencies in the 3D model, guaranteeing optimal printing results. By addressing intricate geometries and resolving issues, non-manifold slicing algorithms enable the seamless translation of digital models into accurate physical representations. Optimisation Techniques The potential of additive manufacturing slicing algorithms has been optimised using various techniques established by researchers and engineers. These methods are intended to improve the manufacturing process’s precision, speed, and quality. Here are a few noteworthy optimisation techniques: Adaptive Layer Thickness As was already said, adaptive slicing modifies layer thickness dependent on the object’s geometry. This feature enables the printing process to produce higher resolution in regions requiring finer details and faster printing speeds in parts with less intricate elements. Infill Optimisation The inside framework of the printed object is referred to as infill. Optimising the infill pattern and density can considerably affect the item’s strength, weight, and material utilisation. Advanced slicing algorithms enable the custom design of infill patterns like honeycomb, grid, or gyroid, each offering a different trade-off between strength and material usage. Support Structure Generation Support structures are frequently needed during printing to prevent the collapse or deformation of overhanging elements or complex shapes. Slicing optimised algorithms can intelligently create support structures only when required, minimising material waste and post-processing work. Printing Path Optimisation Printing speed and overall print quality can be impacted by the order in which the printer puts the materials. Optimisation approaches aim to reduce retraction movements, travel distances, and the printing route to eliminate pointless pauses and starts. The printing time can be decreased through printing path optimisation, increasing productivity and efficiency. Intelligent Cooling Strategies In additive manufacturing, cooling is essential, especially for materials prone to warping or distortion. By altering the printing speed, fan speed, and layer dwell time, slicing algorithms can incorporate adaptive cooling strategies to maximise cooling between layers. This raises dimensional accuracy while reducing thermal stress. Multi-Material Printing Multi-material prints are possible with several additive manufacturing techniques. The exact control of material deposition and transition points made possible by optimised slicing algorithms ensures smooth integration of various materials and minimises flaws or weak interfaces. Post-Processing Considerations To make removal easier or reduce the need for post-processing, slicing algorithms can also optimise the design of support structures. In the final stages of additive manufacturing, this saves time and effort. Conclusion The core of 3D printing is additive manufacturing slicing algorithms, which make it possible to turn digital models into actual products. The choice and optimisation of slicing algorithms substantially impact the quality, speed, and accuracy of additive manufacturing. Engineers and researchers can maximise the potential of additive manufacturing and open new doors in design and manufacturing by using adaptive layer thickness, infill optimisation, support structure generation, printing path optimisation, intelligent cooling strategies, multi-material printing, and post-processing considerations. The advancement of more sophisticated slicing algorithms and optimisation methods will result in additional advancements in print quality, effectiveness, and material utilisation as additive manufacturing progresses. Manufacturers can fully utilise the capabilities of additive manufacturing and promote innovation across various industries by being on the cutting edge of these developments. Ready to optimise your additive manufacturing process? Discover the power of Prescient’s advanced slicing algorithms and optimisation techniques. Contact us today to unlock the full potential of 3D printing and revolutionise your manufacturing capabilities.

Read MoreHow Inspection And Validation Can Improve The Reliability Of Additive Manufacturing Processes

Table of content What Is Meant by Inspection and Validation? 4 Steps to improve Inspection and Validation How Can You Implement Inspection and Validation in Your Additive Manufacturing Process? Conclusion Do you want to make the processes you use for additive manufacturing more reliable? If so, you’ve come to the right place. This article will talk about how you can make your 3D printing more reliable by using inspection and validation.The additive manufacturing method, which is sometimes called “3D printing,” is a business that is growing quickly and changing the way we make things. 3D printing is a popular way to make prototypes and custom parts because it can make complicated shapes and patterns. Still, as with any manufacturing process, it’s essential to make sure that the final product meets quality and reliability standards. At this point, there needs to be an inspection and validation. What Is Meant by Inspection and Validation? During the inspection, the printed item is looked at to make sure it meets certain standards, such as size, finish, and material quality. Validation, on the other hand, is the process of testing the part to make sure it works as expected under different conditions, like stress or heat.Additive manufacturing might be more reliable if there were better ways to inspect and test products. 4 Steps to improve Inspection and Validation 1. Catching Errors Early Inspection is a key part of the process of additive manufacturing because it lets you find mistakes early on. This is important because it could save you money and time in the long run. For instance, if a part is printed in the wrong size, it may be caught early and fixed so that the whole part doesn’t have to be made again or thrown away. If you catch problems early, you may save money and improve the overall quality of your printed parts. 2. Ensuring consistent quality Checking and validating processes make sure that the quality of your printed parts is always good. This is very important if you want to make consistent products that meet your customers’ needs. By regularly testing and certifying your parts, you can find any quality problems and fix them before they get worse. This could make your customers happy and improve the quality of your goods as a whole. 3. Identifying areas for improvement By looking at and testing your additive manufacturing process, you may find ways to make it better. For example, if parts keep failing a certain validation test, you can find out why and make any changes to the printing process that are needed. This could help you improve the performance and dependability of your printed parts, making your customers happier and making your goods work better overall. 4. Increasing Confidence in the Final Product If you use inspection and validation techniques, you might be able to trust the end results more. This is very crucial in fields like medicine and aviation, where dependability is significant. Testing and validation make sure that your products meet the right standards and specifications and work as expected in different situations. This could help you meet client needs, get industry certifications, and build a stronger reputation as a reliable provider. How Can You Implement Inspection and Validation in Your Additive Manufacturing Process? 1. Develop a Quality Control Plan For your additive manufacturing process to work, you need a quality control plan that includes inspection and validation steps. This plan should say what will be checked and how validation tests will be done. The strategy should also say how much error is okay for each of the specs that are being tested. A good plan for quality control can help make sure that everyone who works on the part knows what it is supposed to do. 2. Invest in the Right Equipment For inspection and validation procedures to work, you need to buy the right tools. Measurement tools, test equipment, and software are all examples of this type of equipment. You should choose the equipment based on how your production process works and how precise it needs to be. For example, you might need to buy a coordinate measurement machine (CMM) if you need to figure out the size of something. 3. Train Your Team It’s necessary to show your staff how to use the equipment and go through the same inspection and validation steps every time. During this training, the contents of the quality control plan, the tools and equipment that are used, and the right way to do inspections and validation tests should all be talked about. The training should also cover what to do if a part doesn’t meet the requirements, such as writing down the problem and fixing it. Conclusion Inspection and validation are two important steps that help make additive manufacturing more reliable. You can make 3D printing more reliable by catching mistakes early, making sure the quality is always the same, looking for ways to improve, and having more faith in the end result. Do you want to use additive manufacturing more effectively? Prescient Technologies can assist you! Our software development services could completely change how you use 3D printing and other methods of “additive manufacturing.”So, make a plan for quality control, get the right tools, and train your staff. Then, you’ll be on your way to better 3D-printed products. References: TUVSUD ESCIES Additive Manufacturing Internet of Business

Read MoreDesigning For Additive Manufacturing: Best Practices For Successful Product Development

Table of content Top 8 Best Practices For Successful Product Development Conclusion Top 8 Best Practices For Successful Product Development 1. Start with a thorough understanding of the technology Additive manufacturing has changed how complex parts are made, making it possible to make structures that were once impossible to make. But if you want to make good designs for 3D printing, you need to know how the technology works.For example, you need to know about the build volume, resolution and precision of each 3D printing technology and choose the right materials for your design. Also, you need to think about how the parts will be positioned and held up during the printing process. By thinking about these things, you can make designs that work well with the technology and use all of its features. 2. Optimise parts for the build process Putting together a 3D printer might come with its challenges, which you should think about. For example, you have to think about how the pieces are set up on the build plate to make sure they are supported well when printing. 3. Reduce material usage 3D printing is better than traditional ways of making things in a lot of ways, like being able to use less material. By designing parts to use less material, you can make products that are more environmentally friendly and make less waste. One way to do this is to build with lattices, which are strong but use less material. Putting these structures into designs can help make parts that are light but strong, useful, and long-lasting. 4. Consider post-processing requirements When a 3D print is finished, it may need to be cleaned or finished. It is called “post-processing”. Keep these needs in mind when you’re designing, since they could make the production process take longer and cost more. By making parts that are easy to clean and polish, you can save time and money during post-processing. Also, if components are designed with as few support structures as possible, they may need less post-processing. 5. Optimise for material properties When designing parts for 3D printing, you need to think about how the materials work. During the printing process, for example, some materials may be more likely to bend or change shape, while others may be more likely to break or crack. If the designs work well with the properties of the chosen material, the parts will be strong and useful. 6. Use design software that supports 3D printing A key part of the DFAM process is the use of design software. If you use software made just for 3D printing, you can make designs that work best with the technology. These software tools can help you find problems, like places that might need more support, and give you ideas on how to fix them. 7. Incorporate tolerances Tolerances are the allowed differences from a given dimension that designers must take into account when making things for additive manufacturing. Since the accuracy and precision of 3D printing processes vary, planning with tolerance in mind may help avoid problems like pieces that are too tight or too loose. Tolerances in the design can also help make sure that the pieces fit together right and work as planned. 8. Collaborate with experienced 3D printing partners Working with people who have already used 3D printing can help you make your designs better. These partners can tell you important things about what you can and can’t do with 3D printing technology. They can also show you ways to make your printing more effective and efficient. 9. Test and lterate Testing and iterating are important parts of making a good product, and they are even more important when designing for additive manufacturing. Because 3D printing technologies are always changing, it’s important to keep up with the latest changes and to keep testing and improving designs. With 3D printing, prototypes can be changed and tested quickly, so design flaws can be found and fixed quickly before the product goes into production. Conclusion To design for additive manufacturing, you have to change the way you think about things. When designing for efficient and effective production, 3D printing’s unique strengths and weaknesses must be taken into account. By following the best practices in this article, you can make sure that their parts are good for 3D printing. This will lead to faster production, less material waste and more environmentally friendly products.If you want to elevate your additive manufacturing processes and stay ahead in the competitive market, Prescient Technologies can be your go-to partner. With our state-of-the-art software development services, we can help you get revolutionary results and improve how you use 3D printing and other “additive manufacturing” techniques.Get in touch with us today and take your product development to the next level. References: Alpha Bigrep Radius

Read MoreThe Advantages And Limitations Of Additive Manufacturing: A Comprehensive Overview

Table of content Top 6 Advantages of Additive Manufacturing: Top 6 Limitations of Additive Manufacturing Conclusion In the last few years, 3D printing and additive manufacturing have enhanced the scope of production. 3D printing is the process of putting layers of material together to make things that are three-dimensional. This technology is better than the old ways of making things in a lot of ways, but it comes with its own set of limitations. Here, we’ll look more closely at the top six pros and cons of additive manufacturing. Top 6 Advantages of Additive Manufacturing: 1.Reduced Time and Cost One benefit of additive manufacturing is that it makes production faster and cheaper. Usually, when making a new product, you start by making a prototype, then the tools, and finally the finished product. This process could take a long time and cost a lot of money. But additive manufacturing makes the process go faster. 2.Complex Geometries With additive printing, you can make things that would be hard to make in any other way. Additive manufacturing can be used to make structures with hollow channels inside and curved surfaces.3 3.Customization and Personalization Additive manufacturing makes it possible to change and personalize products. In traditional manufacturing, the same product is made over and over again, and there is no way to change it. Customers can use additive manufacturing to make one-of-a-kind items with their own specs, sizes, and shapes. 4.Reduced Material Waste If additive manufacturing is used, there may be less need to throw away materials. With traditional ways of making things, like subtractive manufacturing, a lot of materials are wasted. In additive manufacturing, just the right amount of material is used. This cuts down on waste and saves money on materials. 5.Faster Prototyping One more benefit of additive manufacturing is that prototyping can be done more quickly. When standard production methods are used, prototyping can take a long time and cost a lot of money. Additive manufacturing can be used to make prototypes quickly and cheaply. You can easily change designs, try out new materials and shapes, and repeat the process. This makes it easier and cheaper to get products to market faster. 6.Simplified Supply Chains Since additive manufacturing makes it possible to make things only when they are needed, supply chains may be easier to run. Instead of making a lot of the same thing and storing it in warehouses, additive manufacturing lets people make things as they need them. This might make people need less storage space and be less likely to keep things they don’t need. Top 6 Limitations of Additive Manufacturing: 1.Limited Materials One problem with additive manufacturing is that it can only print with a certain number of materials at one time. Even though the number of materials is growing, it is still very small compared to conventional methods. This limitation could affect how well the final product works, how long it lasts, and how well it lasts. 2.Surface Quality A glaring limitation of additive manufacturing is that the surface quality of the parts is still not very good. Especially, when complex structures are made, a smooth surface finish is difficult to achieve. 3.Size Limitations With additive manufacturing, the size of objects may be limited. How big an item is depends on how big the printer is and how much room it has to work with. Larger things may need to be printed in parts before they can be put together. This will take time and make the process harder. 4.Complexity Limitations Using additive manufacturing, you can make buildings with complex shapes, but the shapes can only be complicated. Complex designs can be hard to make because they often need more support structures or post-processing steps, which take more time and money. 5.Limited Scale Another problem with additive manufacturing is that it can only make small quantities. Additive manufacturing is great for making small batches of goods, but it’s not ready yet to make a lot of things at once. This is because additive manufacturing is a slow method that might take a long time to make a lot of parts. 6.Environmental Impact When you use additive printing, it might be hard to get rid of things like support structures and failed prints. Also, if the materials used in additive manufacturing are not recycled or thrown away in the right way, they could hurt the environment. Conclusion In conclusion, additive manufacturing is faster, cheaper, more flexible, and wastes less material. It does, however, have a number of flaws, including a paucity of materials, poor surface quality, small size, and complexity issues. Despite these problems, additive manufacturing is an important part of the manufacturing industry and will continue to change and improve over time. Do you want to go to the next level with additive manufacturing? We can help you at Prescient Technologies. Our software development services could change the way you think about 3D printing and other methods of “additive manufacturing.” References:

Read MoreMaximizing the Benefits Of Additive Manufacturing: Strategies For Implementation

Table of content Top 8 Strategies For Implementation Conclusion Want to change the way you make things and take your business to the next level? AM, or additive manufacturing, might be what you need. AM has the power to change your production processes because it can use digital designs to make 3D objects. It creates shorter lead times, lower costs, a better design, and less material waste. But how do you ensure that your business gets the most out of AM? Don’t worry, these top 8 strategies for implementation will help you out. Top 8 Strategies For Implementation 1. Assessing Your Business Needs First, you need to figure out what your business needs. On top of that, you need to figure out how AM could be used and what it could do for you. You will also need to look at how you make things now to see where AM can be used and where it might not be the best fit. Once you know exactly what you want, it is time to choose the right technology. 2. Selecting the Right Technology To get the results you want, you need to choose the right AM technology. With so many choices, it is important to look at the pros and cons of each technology before making a decision. Cost, speed, accuracy, and the right material can be the things to think about. By working with AM service providers who have a lot of experience, you can make smart choices about the technology to use. 3. Designing for Additive Manufacturing To get the most out of AM, parts must also be designed to work best with it. You will need to use the best methods for making parts to do this. It means picking materials that use less material and needs less post-processing. Do not forget that the freedom to design is one of the most exciting things about AM. Making shapes with complex geometries was impossible with traditional manufacturing. 4. Overcoming Implementation Challenges Putting AM into place is not always easy, and problems can come up. From high costs to following quality and rules, many things could go wrong. You should have a thorough implementation plan and work with experienced AM service providers. Put money into training and developing your workforce. With this, you can get past any problems and use AM to its fullest potential. 5. Training and Workforce Development To get the most out of AM, it is important to invest in the knowledge and skills of your staff. Creating a skilled workforce requires a lot of training and opportunities. If you don’t know where to start, it is better to work with experienced AM service providers. They can train your team on what they need to know and how to do it. 6. Scaling Up and Maximizing ROI After you have added AM to your manufacturing process, it’s time to get the most out of it. One great way to do this is to make more of them. Some ways to scale and maximize ROI are to invest in automation and improve your production processes. You should also use data and analytics. You can get the most out of AM and take your business to the next level by always making your approach better. 7. Establishing Quality Control Measures You don’t want to leave the quality of your AM-produced parts to chance. That is why it’s crucial to establish a robust quality control process. After all, your reputation is on the line, and you don’t want to risk producing faulty or substandard parts. By maintaining strict quality control, you can ensure that all parts meet the necessary standards. Trust us; it is worth the investment. By prioritizing quality control, you can cut the risk of defects, reduce waste, and produce consistent, high-quality parts that meet your customers’ expectations. 8. Continuous Improvement and Innovation Don’t get complacent once you’ve implemented AM in your business. Embrace a mindset of continuous improvement and innovation to stay ahead of the game. Always strive to improve your processes and technology and gather feedback from your team and customers. Explore new and creative ways to optimize and innovate. By staying ahead of the game, you can keep a competitive edge and unlock the full potential of AM. Stay on the lookout for emerging AM technologies, materials, and techniques. In short, stay in the loop with the latest trends and innovations. This way, you can future-proof your business and be ready for whatever challenges and opportunities lie ahead. Conclusion Get ready to experience the benefits of additive manufacturing (AM) in your business. But before you dive into it, it is important to plan carefully and take a few steps to ensure success. Start by selecting the right technology for your business needs and designing for AM. Overcome any challenges that may arise during the implementation process. Don’t forget to invest in your workforce and train them in AM technologies to develop a culture of innovation. Once AM is integrated into your business, you can explore ways to scale up production and maximize your return on investment. References:

Read MoreAdditive Manufacturing the rise of metals in 3D printing

Table of content Plastic as the basis for 3D printing Metal as the basis of 3D printing Additive manufacturing is one of the advanced techniques of Industry 4.0 that can manufacture industrial products faster and more precisely as compared to traditional manufacturing processes. Also known as 3D printing, it is a technique that works by turning a digital model of an object into a three-dimensional physical item by adding printable materials layer by layer on its digital design. It helps create complex geometrical patterns that are not possible with traditional manufacturing methods, designing and making lighter components, and controlling various material properties such as density and stiffness. 3D printing has gained popularity rapidly, involving minor prototype construction, fewer dies, and less post-processing. The aerospace and defense industry is experiencing large-scale use of 3D printing with French company Thales Group started a global center of expertise in additive manufacturing in Morocco in 2017. Boeing created its first 3D printed metal satellite antenna for the Israeli company Spacecom in 2019. Airbus used the technology to manufacture the titanium 3D printed bracket on an in series production A350 XWB commercial aircraft in 2017 and has since announced plans to develop 3D printed drones. Plastic as the basis for 3D printing Stereolithography (SLA): SLA is the first 3D printing technology ever used. It hardens a liquid resin using an ultraviolet beam, bonding each successive layer. Despite its antiquity, this technology is still widely used mainly due to a few advantages such as detail resolution, surface quality, and tight tolerances. It is used for UV-sensitive epoxy resins and ceramic-reinforced materials (NanoTool, BlueStone, CeraMax). This technique is widely used for coupling tests, dimensional verification, ergonomic studies, and wind tunnel aerodynamics tests due to its high detail resolution. Fused filament fabrication (FFF): In this process, melted thermoplastic material such as plastic, wax, or metal is sprayed from a nozzle to create many layers, each of which are bonded to the other. The bonding is done mainly by heat or adhesion. The most popular metals used here are nylon, high-density polyethylene, polycaprolactone, polycarbonate, and low melting point metals. Due to its affordability, FFF is a commonly used process for rapid prototyping parts with standard tolerances. Selective laser sintering (SLS): SLS involves hardening and bonding tiny seeds of plastic into layers in a three-dimensional structure using a laser. The powder is jet sprayed from multiple nozzles on the print area, and then the laser fuses or sinters the powder layer by layer. Based on the requirement, SLS printed objects are commonly made with plastic materials, such as nylon or any other powdered material. One of the main benefits of this technique is that, unlike many other 3D printing technologies, SLS doesn’t require much tooling once an object is printed.Unlike stereolithography, SLS doesn’t need additional supports to clasp a thing while it is being printed. Electron beam melting (EBM): Like SLS, EBM is a process that requires high energy high temperature, just that it uses an electron beam as its power source. In this, a tungsten filament in the electron beam gun is superheated to create a cloud of electrons that accelerate to approximately one-half the speed of light. A magnetic field focuses the beam to the desired diameter, while the second magnetic field directs the beam of electrons to the desired spot on the print bed. Currently, EBM is required mainly for producing refractory and reactive metals (titanium, niobium, zirconium, tantalum, etc.) and their alloys. EBM is great for melting and refining metals and alloys in water-cooled copper molds under a high vacuum. Laminated object manufacturing (LOM): Introduced by Cubic Technologies (formerly Helisys Inc.), LOM is a quick and comparatively cheaper method of 3D printing objects in various materials such as metals, plastics, or paper. It binds sheets in successive layers then cuts into the desired according to the 3D CAD model. It is a prototype-centric technique and is not used for production. Metal as the basis of 3D printing While 3D printing started by using mainly plastic as the base material, metal additive manufacturing technologies are currently the most significant growth area for additive manufacturing and include: Selective laser melting (SLM): A laser is used to melt successive layers of metallic powder until completely melted. The machine then adds additional layers of powder over the melted layer until the object is built. The aerospace and medical devices industries have witnessed the maximum use of this technology, as the manufacturing in those industries involves complex parts that can be simplified using this process. This technology was discovered in 1995 by the German research institute Fraunhofer Institute ITL. Direct Metal Laser Sintering (DMLS): Developed jointly by Rapid Product Innovations (RPI) and EOS GmbH, this technique is like SLM. The main difference is the degree to which the particles are melted. In DMLS, the particles are not completely melted. Also, the 3D printer parts are developed from excellent Aluminium or Titanium powder. Laser metal disposition (LMD): Laser Metal Disposition is also called directed energy deposition (DED). In this, a laser beam melts the metallic object and creates a pool into which the powder is fed. The powder then melts to form a deposit, and the required geometry is achieved layer by layer. The powder emitting laser and nozzle are controlled using a motion- centric system or robotic arm. This technology has been rapidly gaining traction in industries such as aerospace, tooling, transportation, and oil and gas. Electron beam melting (EBM): Originally patented and developed by the Swedish company Arcam, EBM differs from other techniques as it uses an electron beam as a power source instead of a laser to 3D print metal. The beam fully melts down the metal powder layer by layer in a high vacuum while retaining the original characteristics of the material. The technique can manufacture metal parts with 100% density and is also helpful for industries with complex components such as aerospace and medical implants.

Read More