Customer Login

Defect Detection

Your Gateway to Zero-Defect Manufacturing

Defect Detection Using Visual Inspection

Detecting defects is crucial for maintaining high-quality standards in manufacturing. Advanced visual inspection systems use high-resolution cameras and image processing algorithms to identify surface imperfections, verify dimensional accuracy, ensure color and texture consistency, check assembly correctness, detect contamination, and validate labels and markings. These automated systems improve defect detection accuracy and streamline quality control. Various methods, from traditional visual inspection and mechanical testing to advanced Ultrasonic Testing, X-ray imaging, Automated Optical Inspection (AOI), and AI-based systems, are used to spot defects. Combining these techniques ensures top-quality products for customers.

various methods used to detect defects

Detecting defects in products involves several methods, each with its own strengths. Traditional techniques like visual inspection rely on human eyes, while mechanical testing measures physical properties. More advanced methods include Ultrasonic Testing (UT) and X-ray imaging, which reveal internal flaws. Automated Optical Inspection (AOI) and AI-based systems use cameras and machine learning to spot defects quickly and accurately. Newer technologies, like infrared thermography and laser scanning, offer precise, non-contact inspections.

Each method has its pros and cons. Combining traditional techniques with advanced AI can provide the best results, ensuring top-quality products for customers.

Revolutionize Quality Control with AI-Powered Visual Inspection for Defect Detection

AI-based visual inspection systems revolutionize quality control across industries by leveraging machine learning and computer vision. They enhance defect detection with unparalleled accuracy and consistency, speeding up inspection processes significantly. These systems also maintain detailed records for compliance and quality tracking, scale effortlessly with large product volumes, and reduce labor costs by minimizing manual inspections. This technology marks a significant advancement in ensuring product quality and efficiency for businesses in the USA.

Embrace AI-powered visual inspection and step into the future of quality control with prescient technology.

How It Works

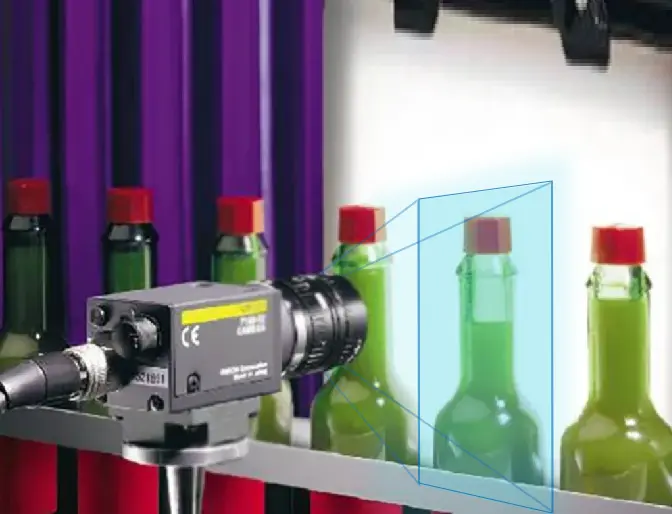

Capturing Images

- High-resolution cameras take detailed pictures or videos of products.

- These images cover all angles and lighting conditions to make sure no defect goes unnoticed.

Enhancing Images

- The system cleans up the images, making them clearer and easier to analyze.

- It focuses on the most important parts where defects are likely to show up.

Spotting Key Features

- The AI identifies important features in the images, like edges, textures, colors, and shapes.

- Advanced methods, especially Convolutional Neural Networks (CNNs), can automatically learn what to look for in each image.

Detecting and Classifying Defects

- The AI has been trained on thousands of images, learning to distinguish between defective and non-defective products.

- It quickly identifies any anomalies, pinpointing the exact type and location of defects.

Taking Action

- Once a defect is found, the system categorizes it by severity and type.

- It can automatically remove defective items from the production line or alert human operators for further inspection.

Seamless Integration

- This AI system works with existing manufacturing and quality management systems.

- It can adjust production settings in real-time to reduce future defects.

Benefits

Unmatched Accuracy

AI systems detect defects with higher precision and consistency compared to human inspectors.

Faster Inspections

Automated systems can process more items in less time, boosting overall efficiency.

Detailed Reporting

Keeps meticulous records of inspections, helping with compliance and quality tracking.

Scalable Solutions

Easily handles large volumes of products without a drop in performance.

Cost Savings

Reduces labor costs by minimizing the need for manual inspection.

Defect Detection in Different Industries

Manufacturing

Finds surface defects, assembly errors, and misaligned parts.

Electronics

Inspects circuit boards, solder joints, and semiconductor wafers.

Automotive

Detects paint flaws, scratches, and structural issues.

Pharmaceuticals

Checks packaging, labels, and tablet quality.

Unlocking Competitive Edge AI-Powered Visual Inspection in US Businesses

For businesses in the USA, AI-powered visual inspection is more than just a technological upgrade—it’s a competitive advantage. By enhancing accuracy, speed, and cost-efficiency in quality control, this technology ensures that only the best products reach your customers, boosting satisfaction and loyalty.

Frequently Asked Questions (FAQs)

What is defect detection in manufacturing?

Al defect detection uses advanced algorithms and machine learning techniques to automatically identify defects in manufacturing processes with high accuracy and efficiency.

How does Al defect detection work?

KBE can help businesses automate design processes, improve product quality, and reduce design cycle times. By automating design processes, KBE can help businesses stay competitive and meet customer demands.

Why choose Prescient Technologies for surface detection?

Prescient Technologies offers cutting-edge solutions for surface detection using innovative technology and expertise to enhance manufacturing quality and productivity.

What is visual defect inspection?

Visual defect inspection is a technique that involves using cameras and image processing algorithms to detect and analyze defects in products based on visual characteristics.

Get in Touch for AI-Powered Quality Assurance Solutions

- Data Matters: High-quality images and accurate labels are essential for training the AI.

- Flexibility is Key: The system must adapt to different product designs and production conditions.

- Smooth Integration: Must work seamlessly with your current systems and processes.

- Transparency:It’s important that AI decisions are clear and understandable to build trust and meet regulatory standards.

- Pharmaceuticals: Checks packaging, labels, and tablet quality.