CAD Software Development for Automotive Simulation: Accelerating Design Validation

- Home

- Blog Details

- July 14 2023

- admin

Table of Content

Introduction

The Role of CAD Software in Automotive Simulation

- Accelerating Design Validation

- Enhanced Visualization

- Virtual Testing and Analysis

- Iterative Design Process

- Collaboration and Communication

- Cost Reduction

Challenges and Future Trends

- Complexity and Integration

- Real-Time Simulation

- Virtual Reality (VR) and Augmented Reality (AR)

- Artificial Intelligence (AI) and Machine Learning (ML)

- Data Management and Security

The Role of CAD Software in Sustainable Automotive Design

Conclusion

Introduction

The automobile sector has always been on the cutting edge of technical development, continually pushing the envelope of innovation. Design validation ensures that new vehicle designs adhere to safety, performance, and legal criteria and is essential to automotive development.

Computer-aided design (CAD) software, integrated with KBE principles, has revolutionized automobile simulation, significantly expediting the process and enhancing accuracy. Knowledge-based engineering incorporates design rules, engineering knowledge, and optimization algorithms into CAD software, empowering engineers to automate and streamline the design validation process.

In this post, we’ll look at the importance of CAD software development in the automobile sector and how it affects design validation.

The Role of CAD Software in Automotive Simulation

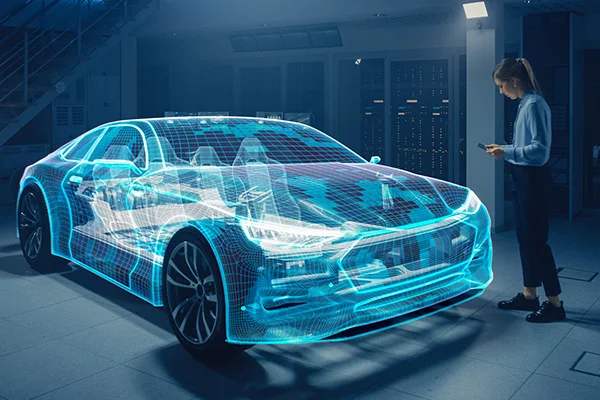

Computer-aided design (CAD) software enables automotive engineers and designers to create, modify, and analyze vehicle components and systems in a virtual environment. By utilizing CAD software, automotive manufacturers can simulate various scenarios and evaluate the performance and behavior of different design options before physically building prototypes. This virtual prototyping process significantly accelerates design validation by identifying potential issues early in the development cycle.

- Accelerating Design Validation

Let’s explore the key points highlighting how CAD software expedites the design validation process, enhances accuracy, promotes collaboration, and ultimately drives efficiency in automotive design and development. Let’s dive in and discover the power of CAD software in accelerating design validation.

- Enhanced Visualization

CAD software offers advanced visualization capabilities, allowing designers to create highly realistic 3D models of vehicles and their components. This level of visual fidelity enables engineers to examine the design from multiple angles and identify potential clashes, interferences, or design flaws. By detecting these issues early, the development team can make necessary adjustments swiftly, saving time and resources.

- Virtual Testing and Analysis

CAD software offers potent simulation tools that allow testing and analyzing car designs virtually. Crash tests, aerodynamic performance, structural integrity, and thermal analysis are real-world situations that engineers can model. These simulations enable design modifications to improve safety, efficiency, and overall performance by demonstrating how the vehicle might behave in various conditions.

- Iterative Design Process

By leveraging CAD software, designers gain the ability to make design modifications and evaluate their impact on the final product. This approach significantly reduces the time required compared to manual prototyping methods. The design validation process is greatly accelerated with the ability to test multiple iterations, assess their viability, and implement necessary improvements. The iterative nature of CAD empowers designers to expedite the development cycle and enhance the overall efficiency of product design and validation.

- Collaboration and Communication

CAD software enables seamless collaboration and communication among various stakeholders in the design validation process. Designers, engineers, and manufacturers can work together on a virtual platform, sharing design files, annotating, and providing real-time feedback. This collaborative environment improves efficiency, reduces miscommunication, and ensures everyone is on the same page, further expediting the design validation process.

- Cost Reduction

CAD software development for automotive simulation is crucial in reducing development costs. By identifying design flaws and issues early in the virtual prototyping stage, manufacturers can avoid expensive physical prototypes and costly rework. CAD software enables engineers to optimize designs for manufacturability, assembly, and materials, leading to cost savings during production.

Challenges and Future Trends

A thorough understanding of CAD software development is vital for your design skills to achieve maximum potential. By following key points, you can tap the true potential of CAD software development and improve your design abilities.

- Complexity and Integration

CAD software must advance to handle the delicate relationships between many components as vehicle systems become more complex. A fluid workflow and accurate design validation depend on integration with other software tools, such as computer-aided engineering (CAE) and computer-aided manufacturing (CAM).

- Real-Time Simulation

The automotive industry is moving towards real-time simulation, where virtual testing can be performed accurately and quickly. CAD software developers must enhance simulation capabilities to provide real-time feedback during the design process, enabling faster iterations and better decision-making.

- Virtual Reality (VR) and Augmented Reality (AR)

VR and AR technologies VR and AR technologies can revolutionize the design validation process. By immersing designers and engineers in virtual environments, CAD software can provide an enhanced understanding of the design and its performance. Incorporating VR and AR capabilities into CAD software will offer a more intuitive and immersive experience, leading to better design decisions.

- Artificial Intelligence (AI) and Machine Learning (ML)

Automation of some steps in the design validation process is possible with the help of AI and ML algorithms. AI-driven algorithms, for instance, may examine a lot of simulation data to find patterns, refine designs, and provide suggestions for enhancements. It’s possible to hasten the design validation process and increase overall efficiency by integrating AI and ML capabilities into CAD software.

- Data Management and Security

Effective data management and security have become crucial with the increasing reliance on digital design data and collaboration. CAD software development must address challenges related to data organization, version control, and secure data sharing among different stakeholders. Implementing robust data management systems and ensuring data security protocols will be paramount to protect valuable intellectual property and maintain confidentiality.

The Role of CAD Software in Sustainable Automotive Design

With an increasing focus on sustainability in the automotive industry, CAD software enables sustainable design practices. By facilitating virtual prototyping and simulation, CAD software reduces the need for physical prototypes, thus minimizing material waste and carbon footprint. The accurate analysis provided by CAD software helps optimize designs for energy efficiency, lightweight, and eco-friendly materials.

Additionally, CAD software promotes team collaboration and communication, enabling seamless integration of sustainability considerations throughout the design validation process. Through its capabilities, CAD software empowers automotive manufacturers to embrace sustainable practices and develop environmentally conscious vehicles for a greener future.

Conclusion

The emergence of automotive simulation CAD software integrated with Knowledge-Based Engineering (KBE) is pivotal in accelerating design validation processes. This advanced CAD software equips automotive engineers and designers with a wide range of tools and functionalities to expedite development timelines and reduce costs. It empowers them to streamline design validation, improve efficiency, and deliver high-quality automotive solutions in a cost-effective and time-efficient manner.

As technology continues to advance, KBE-driven CAD software addresses challenges. It embraces future trends like real-time simulation, VR/AR, and AI/ML, further enhancing CAD software’s capabilities and leading to even more efficient design validation in the automotive industry.

Supercharge your design validation process with Prescient CAD software: experience faster iterations, enhanced accuracy, and seamless collaboration. Revolutionize your automotive design today!