Why CAD Customization is needed

- Home

- Blog Details

- April 9 2019

- admin

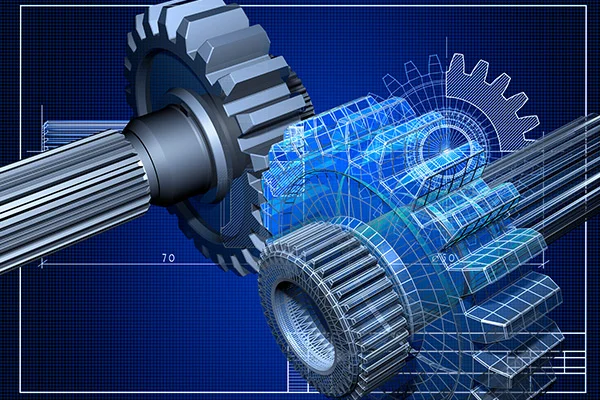

As previously stated; one might encounter complex design situations in engineering scenarios. Earlier, designs were drawn on sheets with pen and necessary scaling instruments and manufactured manually using old school techniques. But now, with the advent of CAD customization, the entire work-process has become easier and smoother than ever.

When CAD customization is integrated in CAD software application, a number of advantages occur. With CAD customization, the production of a drawing and design of a mechanical component can be generated with great accuracy. This facilitates the engineers to have tools to make quick modifications to any issues found in the design. The design can be customized according to the needs outlined before or after the CAD design is generated.

Need for CAD Customization

Implementing a functionality that does not exist in the OOTB package: The activity of CAD customization is carried out when a particular organization needs tailor made CAD software to address their need. It might be a separate functionality that a specific task needs or it might be about a format.

- Repetitive tasks can be done in a single click: Working on a product using CAD software can involves repetitive actions. This often ends up consuming a lot of time. Although, most CAD software provides generic features, one can have it customized for specific functions that repeat more like a loop.

- Checklist for inspection can be customized: You can reinvent the way you conduct by creating smart inspection templates. This aids in streamlining the quality and documentation processes even more.

- Wizards can be created for guiding the use through the complete workflow: Wizards are used to properly set something up. In some cases, wizards are used for setting up all tool-path and drilling operations within the CAD-CAM system. CAD customization can setup automated wizards for carrying out repetitive tasks and regression testing without having to put in extra emphasis and time on those, thus completing a workflow without human intervention.

- Big time saving impact: Companies have the capability to automate design, process, and systems integration when customizing CAD software. With customization of CAD functions, companies automate redundant tasks and experience great time savings.

- Core focus on product development: CAD customization allows engineers to keep their prime focus on product development without having to worry about support functions.

- CAD Customization effect on digital thread: CAD customization and automation of CAD software propels advancement in areas such as the digital thread.

Challenges with CAD customization

Like every other entity out there, CAD customization comes with its own drawback. One big challenge with CAD customization is keeping it in sync with the latest technology in the market. Also, every CAD software is gets its new releases so it becomes quite hectic to keep a check and customizing accordingly. We have learned before how add-ons/plug-ins has been introduced to add new features to CAD software. Such add-ons are also prone to updates which need to be worked upon to make it compatible with customized software. Modern technology, however, is working its way towards making the process of updating and customizing a more lenient process.