Types of Geometric Modeling

- Home

- Blog Details

- September 4 2019

- admin

The previous edition gave a brief introduction to Geometric Modeling and its features. Geometric modeling is the mathematical representation of an object’s geometry. It incorporates the use of curves to create models. It can be viewed either in 2D or 3D perspective. The general design is applied to different geometric structures, including sets and graphs. This article introduces geometric models which represent geometric objects and their properties mathematically. They can be viewed as collections of squares of different colors. On the other hand, geometric shapes can be considered mathematical equations. Geometric models can represent data in context, such as a digital image.

Regardless of the modeling approach, all students should understand how CAD software works. A basic understanding of geometric modeling is essential for any aspiring designer. In contrast, button- push robots often neglect this aspect of CAD training. However, preparing students with the fundamental knowledge of geometric modeling is also critical for their competitive edge.

This edition details the primary types of geometric modeling. Geometric modeling can be classified into the following:

Solid Modeling

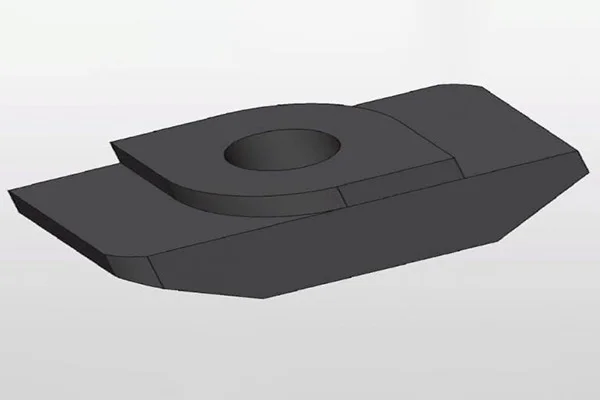

Also known as volume modeling, this is the most widely used method, providing a complete description of solid modeling. Solid modeling defines an object by its nodes, edges, and surfaces; therefore, it gives a perfect and explicit mathematical representation of a precisely enclosed and filled volume. Solid modeling requires topology rules to guarantee that all covers are stitched together correctly. This geometry modeling procedure is based upon the “Half-Space” concept.

A solid model begins with a solid, which is then stitched together using topology rules. Solid modeling has many benefits, including improved visualization and functional automation. CAD software can quickly calculate the actual geometry of complex shapes. A cube, for example, has six faces, a radius of 8.4 mm, and many radii. It has many angles and a shallow pyramid on each face. By applying solid modeling concepts, CAD programs can quickly calculate these attributes for a given cube. Similarly, a cube with rounded edges has many radii and faces.

There are two prevalent ways of representing solid models:

Constructive solid geometry: Constructive solid geometry combines primary solid objects (prism, cylinder, cone, sphere, etc.). These shapes are either added or deleted to form the final solid shape.

Boundary representation: In boundary representation, an object’s definition is determined by its spatial boundaries. It describes the points, edges, and surfaces of a volume and issues the command to rotate and sweep bind facets into a third-dimensional solid. The union of these surfaces enables the formation of a surface that explicitly encloses a volume. Solid Modeling is the most widely used geometric modeling in three dimensions, and it serves the following purpose:

- Solid modeling supports weight or volume calculation, centroids, moments of inertia calculation, stress analysis, heat conduction calculations, dynamic analysis, and system dynamics analysis.

- Solid modeling supports the generation of codes, robotic and assembly simulation

- Solid modeling stores both geometric and topological information; it can verify if the two objects occupy the same space

- Solid modeling improves design quality, enhances visualization, and has the potential for functional automation and integration.

Different solid modeling techniques are as follows:

- Constructive Solid Geometry

- Boundary Representation

- Feature-based modeling

- Primitive Instancing

- Cell decomposition, spatial enumeration, octree

Surface Modeling

Surface modeling represents the solid appearing object. Although it is a more complicated representation method than wireframe modeling, it is not as refined as solid modeling. Although surface and solid models look identical, the former cannot be sliced open the way solid models can be. This model makes use of B-splines and Bezier for controlling curves.

When polygons or NURBS represent surfaces, the computer can convert the commands into mathematical models. These models are saved in files and can be opened for editing and analysis at any time. The process of importing models from other programs is often complex and problematic, resulting in ambiguous results. In contrast, surface modeling allows for precise changes to difficult surfaces.

A typical surface modeling process involves the following steps:

- Generation of a model combining the three-dimensional surfaces and solids.

- Conversion of the model to surfaces, taking advantage of associative modelling.

- Validation of imperfections with surface analysis tools.

- Reconstructing surfaces of objects to apply smoothness to the object.

Surface modeling is used to:

- To shape the design and representation of complicated objects such as a car, ships, and airplane bodies, as well as castings.

- Surface modeling, in contrast, allows users to see the complete surface points at a time. It also allows you to control the exact contour of just a single face.

- There are situations where models imported from another CAD system usually lack details of the features it comprises. If the surfaces are complex, applying changes to this type of geometry can be quite the task. In such cases, surface modeling techniques can be used on one or more faces of the model to make the desired changes.

- Surface modeling enables building one face at a time so that one can control the exact contour and direction of any face. This feature comes in handy at a time when a solid modeling technique fails to create the complex shape of a feature as it builds up several sides of the shape at once.

- As it is not limited to the direct construction of a model face, surfaces can also be used as a reference geometry in a transitional step towards creating the required model face.

- Now, another modeling technique requires a combination of solid and surface modeling techniques to create a solid model. This technique generally involves starting the model as a solid and using surfaces to modify it. Or changing the solid to surfaces to shape and contour it, then turning it back to a solid when done.

Geometric surface modeling has proven to be extremely useful in computer graphics. Multiresolution modeling involves the generation of various surfaces at different levels of detail and accuracy. The resulting surfaces are then applied to various problems, including general surface estimation from structured and unstructured data. One such application is a subdivision surface, which begins from a simple primitive and gradually adds tools and details.

Wireframe Modeling

A wireframe model is composed of points, lines, curves, and surfaces connected by point coordinates. Because the model is not solid, it is difficult to visualize, but it helps generate simple geometric shapes. The resulting model contains information on every object’s point, edge, face, and vertices. This model is beneficial for creating an orthographic isometric or perspective view. The lines within a wireframe connect to create polygons, such as triangles and rectangles, representing three-dimensional shapes when bound together. The outcome may range from a cube to a complex three-dimensional scene with people and objects. The number of polygons within a model indicates how detailed the wireframe 3D model is.

Wireframe modeling helps in matching a 3D drawing model to its reference. Planar objects can be moved to a 3D location once they have been created. It allows the creator to match the vertex points to align with the desired reference and see the reference through the model. Although Wireframe modeling is a quick and easy way to demonstrate concepts, creating a fully detailed, precisely constructed model for an idea can be highly time-consuming. If it does not match what was visualized for the project, all that time and effort is wasted. In wireframe modeling, one can skip the detailed work and present a very skeletal framework that is simple to create and apprehensible to others.

Using a wireframe model as a reference geometry will help you create a solid or surface model that follows a definite shape. In this way, you can easily visualize your model and select objects. The wireframe model is decomposed into a series of simple wireframes and the desired face topology.