Reverse Engineering Inspection and its use

- Home

- Blog Details

- January 17 2019

- admin

The quality control and inspection process in reverse engineering usually take three steps to determine if the 3D CAD model of the part is available or not. Those three steps are as follows:

- The first step involves scanning the part and generating a computer model’s point cloud format.

- The second step involves merging and aligning the two computer models (CAD and Scanned one) to validate the part’s specifications.

- The final step, i.e., step three, includes visual computer model inspections and alignment of the merged models for any deviations in the geometry and dimensions.

- The quality control outcome would be some recommendations for corrections, so the part meets perfectly with the blueprint specifications before the part’s mass production.

Following are some uses of Reverse engineering inspection:

- Reverse engineering inspection comes in handy while carrying out Zero Article Inspection or ZAI. Zero article inspection is a type of workflow where the upcoming physical part doesn’t follow the master design model but rather a derivative of the master model due to fluctuations in dimensions and tolerances. The review of the last digital representation before downstream purposes is known as zero article inspection. In this case, reverse engineering inspection provides sufficient information, allowing the inspector to check tolerances, dimensions, and any other information relevant to such projects. It gives assurance and confidence to produce quality components.

- Reverse engineering inspection is an essential inspection of stylized parts/surfaces – where just dimensional inspection is not enough.

- Reverse engineering inspection is an essential player during First Article Inspection (FAI). During the part manufacturing process, when an issue is detected with the manufactured part, the notification of the same has to go back to its design. The purpose is to keep the 3D CAD model in sync with the actual piece as manufactured. The hybridization of reverse engineering and inspection makes such updates easy to convey and apply, plus keeps the feedback circle opens across departments.

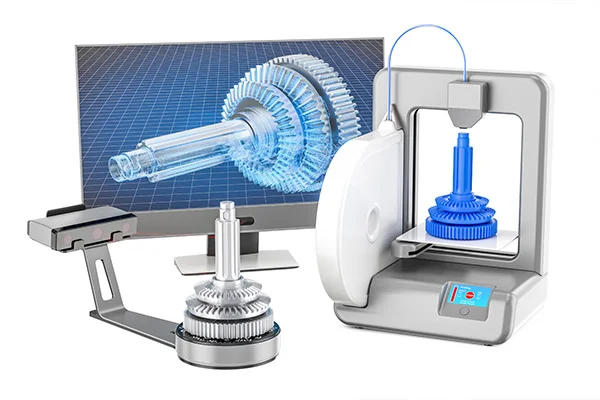

- Reverse engineering inspection has found significant use in the additive manufacturing industry. Such a process helps bring down process-generated errors while calibrating & modifying building criteria to cut down the process itself’s influence.

- adminhttps://www.pre-scient.com/us/author/webwideit/

- adminhttps://www.pre-scient.com/us/author/webwideit/

- adminhttps://www.pre-scient.com/us/author/webwideit/

- adminhttps://www.pre-scient.com/us/author/webwideit/

Tags

Reverse Engineering