machineCONNECT – Remote Monitoring Software for U.S. Manufacturers

Manufacturing in the U.S. faces constant pressure. Machines stop. Production slows. Costs rise. machineCONNECT offers a clear answer. It is remote monitoring software built for U.S. manufacturers, CEOs, and factory owners.

The software connects machines to a central platform. It shows real-time data from the shop floor. It helps detect problems before they stop production. It also provides performance reports that guide better decisions.

Smart Remote Machine Monitoring System

Every machine produces valuable data. This data often goes unused. machineCONNECT turns that data into insights.

a) Monitor machines remotely in real time

b) Detect faults before they become failures

c) Track performance across multiple sites

d) View all critical data from one dashboard

The software uses Industrial Internet of Things (IIoT) technology. It works with existing systems inside a factory. The setup is simple and does not interrupt daily work.

Key Features of machineCONNECT

Real-Time Monitoring

The system delivers live updates on machine status. Managers see how equipment performs at any moment. Early warnings help keep downtime low.

Fault Detection

Smart analytics identify small defects. These alerts help teams act fast. Repairs happen before breakdowns cost time and money.

Performance Analysis

Detailed reports show how machines perform over time. Leaders compare data, improve processes, and increase efficiency.

Seamless Integration

The software fits with ERP and control systems already in place. Factories keep running as usual. No major changes are required.

Scalable Solution

The system supports one factory or many. It grows as the business grows. This makes it a long-term choice.

Benefits for U.S. Manufacturers

Remote monitoring software brings clear results.

a) Reduced downtime through early detection

b) Higher productivity from better machine performance

c) Lower maintenance costs through smart scheduling

d) Faster issue resolution through remote diagnostics

These results improve return on investment. They also support stronger planning at the executive level.

Why U.S. Manufacturers Choose machineCONNECT

CEOs and factory owners in the U.S. look for solutions that add value. machineCONNECT helps them reach this goal.

a) Built with advanced IIoT technology

b) Reduces downtime and lowers costs

c) Detects even minor machine faults

d) Improves efficiency across production lines

Executives see real data instead of guesswork. Operators solve problems faster. Owners protect their investments.

Why Partner with Prescient Technologies?

Prescient has more than 25 years of experience in product engineering. The company has helped U.S. enterprises improve operations and systems.

25+ years of engineering expertise

Teams with deep industry knowledge

Complete consulting, setup, and support

Flexible models for U.S. businesses

Prescient teams know U.S. manufacturing challenges. They deliver solutions that work in real factories.

What is machineCONNECT?

? machineCONNECT is remote monitoring software that provides real-time visibility of machines for U.S. manufacturers.

How does remote monitoring software help CEOs and factory owners?

It reduces downtime, lowers repair costs, and supports faster decision-making.

Can machineCONNECT connect with ERP systems?

Yes. It integrates smoothly with ERP, MES, and factory automation systems.

Is machineCONNECT suitable for large U.S. plants?

Yes. It works for both single factories and large multi-site operations.

Get Started

Factories lose money when machines fail. machineCONNECT reduces that risk. It supports real-time monitoring, fault detection, and performance analysis. U.S. manufacturers, CEOs, and factory owners gain better control over their operations.

Featured Posts

Introduction Interaction with 3D Product Configurators What are 3D Product Configurators? Boosting sales and satisfaction Introduction Customers are often reluctant to buy customized products because...

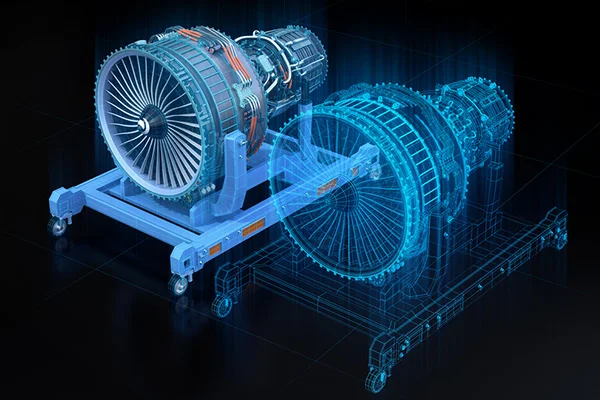

By Swanand Javadekar A digital twin is a dynamic representation of an asset that allows us to understand the better working of the system and predict performance for better design directions. A...

For starters, digitization is converting of analog/physical things such as paper documents, microfilm images, photographs, sounds and more into digital (bits and bytes) version. So it is simply...

Allow us to help you!!

Prescient Technologies does not share or disclose your information to third parties. We value your privacy.